Colour and Gulal Dryer

Product Details:

- General Use DRYER

- Material Stainless Steel

- Capacity 1 T/hr

- Click to View more

Colour and Gulal Dryer Price And Quantity

- INR

- 1 Unit

Colour and Gulal Dryer Product Specifications

- 1 T/hr

- DRYER

- Stainless Steel

Colour and Gulal Dryer Trade Information

- 10 Unit Per Year

- 3 Months

Product Description

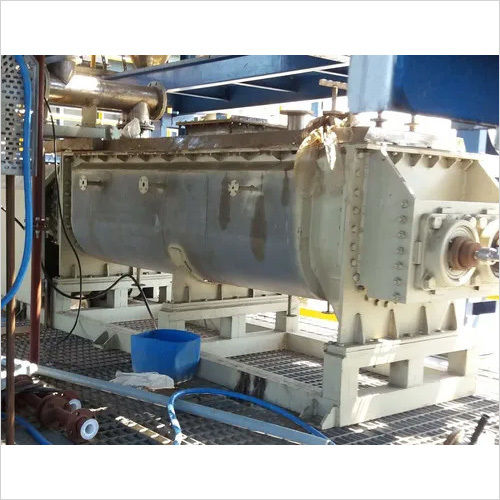

Voice engineers design and manufacture Dustless Continuous Conductive Dryers( CCD ) for Gulals and Colour Dryer Manufacturers.

Presently colours & gulals are dried in dryers, like, Tray, Rotary, Flash and Fluidized Bed. These Colour Dryer Manufacturers consume comparatively not only much more fuel and power, but also create dust problem. Further, due to excessive exposure to hot air, the colours may lose some of their brightness. In CCD, drying is done by conductive method, and not by hot air. So, dusting does not take place. For colours and gulals where drying can be done above 100 deg C, only a little amount of scavenging air is required at the top of the dryer to drive away evaporated moisture. Vacuum version of CCD is used for products where drying need be done at low temperature below 100 deg C. Here Colour Dryer Manufacturers takes place in absence of air. This ensures better& intense color and absolutely no dusting.

The wet feed is continuously agitated by the heated rotating blades, thus exposing new areas to heating surfaces. This results in the moisture boiling off and rendering the wet material dry to the required degree. CCD is a low-speed horizontal indirect dryer/cooler suitable for heating and drying slurry, filter cakes, pastes, powders and granulates. It's fast and very effective.

Special Features of CCD for Gulals and Colour Dryer Manufacturers :

- Very high evaporation capacity

- Very high thermal efficiency

- Dustless drying

- Continuous operation

- Compact installation

- Low fuel & power consumption

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Dryers Application Wise' category

|

VOICE ENGINEERS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send SMS

Send SMS