Rotary Dryer

Product Details:

Rotary Dryer Price And Quantity

- 1 Piece

- INR

Rotary Dryer Trade Information

- 4 Piece Per Day

- 4 Days

Product Description

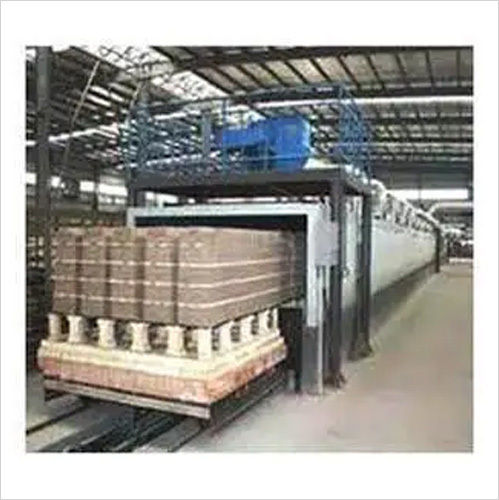

Voice Engineers is Rotary Dryer Manufacturers. It is classified as direct or indirect (air heating method), current or counter current (material air contact).

Direct Rotary Dryer Manufacturers operates on the principle of lifting and showering the product through a hot gas stream moving either in parallel or counter flow. The indirect is more useful to small dusty materials. In indirect dryer, there is little or no contact between the product and drying gases as they are heated from the outside the chamber through a stationary jacket fitted with either multiple burners or other external heat source.

Rotary Dryer Manufacturers not only reduces moisture content in the product but is also able to heat up the material, stimulating a reaction between two or more materials. This type is known as Rotary Kiln or Rotary Calciner. The Rotary Dryer Manufacturers is driven through a girth gear and tyre arrangement. Seales are provided at the ends to ensure minimum air leakage.

The advantages of rotary dryers are:

- Low operating costs

- Low maintenance costs

- High thermal efficiency

Typical products handled:

- Sand

- Clays

- Maize germs

- Coal

- Ores

- Industrial sludges

Rotary Dryers fall into three main categories:

- Rotary Cascade Dryers, where material is lifted and cascaded through a hot air stream.

- Rotary Louvre Dryers, where the hot air stream is passed through a 'rolling' bed of material.

- Rotary Steam Tube Dryers, where material is lifted and cascaded through a rotating steam tube bundle

Rotary Dryers have a similar construction, consisting of a rotating shell fitted with tyres running on a set of support rollers, with a chain or spur gear ring drive.

Specification

| Automatic Grade | Automatic, Semi-Automatic |

| Design | Customized |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Dryers-Systems Wise' category

|

VOICE ENGINEERS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send SMS

Send SMS