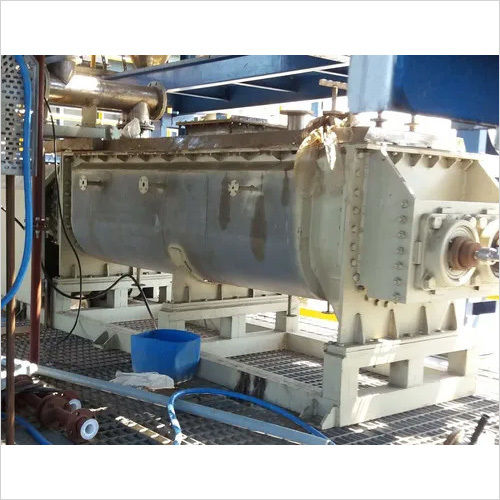

Brick Dryer

325000 INR/Unit

Product Details:

- General Use DRYER

- Material Stainless Steel

- Capacity 1 T/hr

- Click to View more

X

Brick Dryer Price And Quantity

- 1 Unit

- 325000 INR/Unit

Brick Dryer Product Specifications

- Stainless Steel

- DRYER

- 1 T/hr

Brick Dryer Trade Information

- 10 Unit Per Year

- 3 Months

Product Description

Brick Dryer Manufacturers

- Bricks made from fly ash or suitable industrial sludge are required to be properly dried before being used.

- Clay bricks are dried for removal of excess moisture before firing the brick. Otherwise, water will burn off too quickly during firing, causing cracking.

- Voice Engineers offer Brick Dryer which use cars to move the brick through humidity-controlled zones that prevent cracking. This consists of a long chamber through which the bricks loaded in trolley are slowly pushed. Forced Draft fan-circulates hot air into the chamber, speeding up the drying process.

Firing of Dried Clay Bricks

- Dried clay bricks loaded on cars on coming out of the tunnel dryer are introduced seamlessly on a continuous basis into high temperature furnaces called kilns. Kilns are fired using solid fuels such as bio fuel and coal.

- On completion of firing process, the bricks are cooled and stacked. Stacking can be done both manually and mechanically. In modern brick manufacturing plants, automated setting machines are preferred to cut on the costly labour.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Dryers Application Wise' category

|

VOICE ENGINEERS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send SMS

Send SMS