Bagasse Dryer Price And Quantity

- 3500000 INR

- 1 Unit

Bagasse Dryer Product Specifications

- 1 T/hr

Bagasse Dryer Trade Information

- 10 Unit Per Year

- 3 Months

Product Description

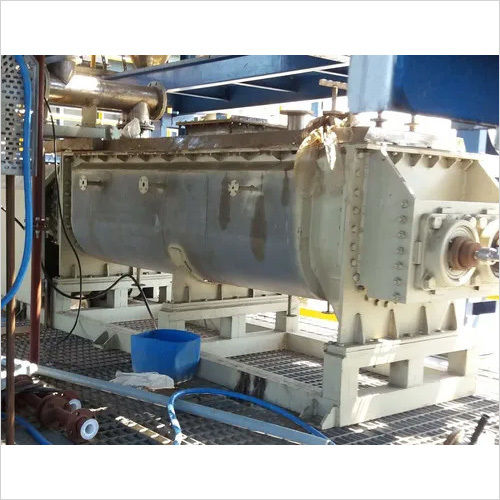

Bagasse Dryer Manufacturer or adiabatic or contact type dryers, transfer heat by direct contact of the product with the hot gases. The gas transfers sensible heat to provide the heat of vaporization of the moisture present in the solid. It is possible to obtain some non-luminous radiation heat transfer benefit also in this case, since the moisture content in bagasse is quite high.

A state of the art sugar cane Bagasse Dryer Manufacturer has been developed by Voice Engineers Limited.

Flue gas required for process is taken from the exhaust of the I.D. fans of the boiler or from a bagasse based special purpose furnace or boiler, and injected at the beginning of the dryer through a device for ensuring the safety of the system.

With the help of blowers, hot air or flue gases fluidize the wet Bagasse Dryer Manufacturer, dry them and discharges the dried product from the other end of the dryer. Moisture laden air is sucked out through a cyclone separator in which the bagasse dust is collected and discharged from its bottom by a rotary air lock valve.

Specification

| Automatic Grade | Semi-Automatic, Automatic |

| Design | Customized |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Dryers Application Wise' category

|

VOICE ENGINEERS LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send SMS

Send SMS